In the dynamic world of Interactive Flat Panel Display, the choice of anti-glare (AG) glass plays a crucial role in the user experience. As a leading manufacturer, we know how important it is to provide our professional customers with in-depth knowledge so that they can make informed decisions. In this article, we explore the intricacies of AG glass, specifically comparing etched and spray-coated options, to help our valued customers select the optimal solution for their needs.

Why we need to use AG glass on Interactive Flat Panel Display?

IFPD is becoming increasingly popular in classrooms. Many classrooms have done away with electronic whiteboards and installed IFPD. This brings a lot of fun to teaching, but also some problems. For example, before IFPD were replaced, schools generally used IWB ( Interactive WhiteBoard )as an interactive teaching tool. The IWB projected images onto the enamel board of the IWB via a projector, and the images were diffusely reflected and eventually seen by the students' eyes. Since the IFPD is made of glass, it is impossible for many students to see the screen clearly due to the reflection of other light in the classroom (classroom lighting, outdoor sunlight), and the highly reflected light can also affect students' vision. For this reason, the use of anti-glare glass on classroom equipment is a necessity.

What is AG Glass?

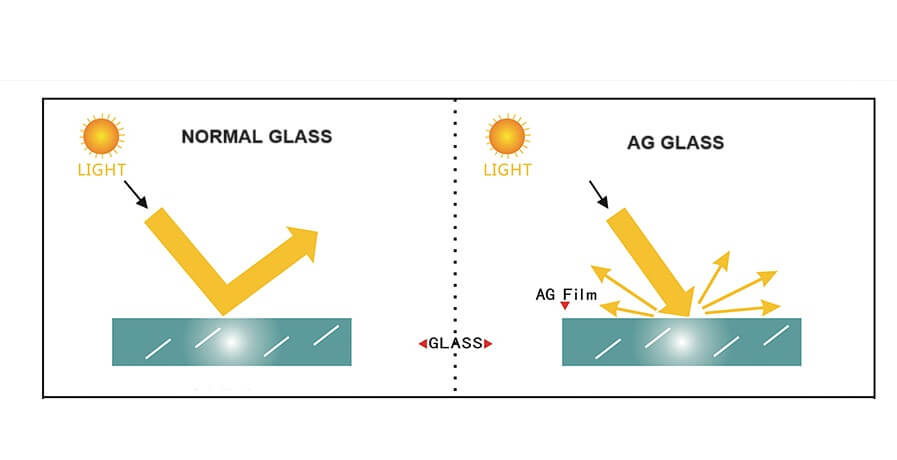

AG glass, also known as non-reflective or low-reflective glass, undergoes a special surface treatment. This type of glass is created by processing one or both sides of high-quality original glass to achieve a lower degree of reflection compared to standard glass. With light reflection reduced from 8% to less than 2%, AG glass provides a clear and transparent visual space that enhances the viewer's visual experience.

Chemically etched AG glass and sprayed AG glass: most commonly used in IFPD

The anti-glare property of AG glass is achieved through various manufacturing processes, such as chemical etching, spraying, coating or other surface treatments. These processes create a textured surface on the glass that scatters the light and thus reduces reflections and glare.

For IFPD, we normally use chemically etched AG glass and sprayed AG glass.

Find out more about the processing methods and their characteristics here.

Sprayed AG glass.:

Processing Methods:

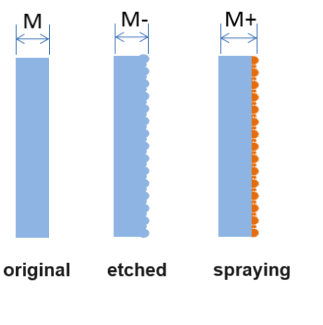

As the name suggests, use a spray gun or similar device to apply the anti-glare solution evenly to the glass surface. The spraying process should be uniform to ensure even anti-glare properties over the entire glass.

Properties:

1.Uniform application: Spraying enables a more even application of the AG coating and ensures uniform anti-glare properties across the entire pane.

2.Cost-effectiveness: This processing technology is convenient and efficient, offering fast production throughput at low cost.

Chemically etched AG glass:

Processing Methods:

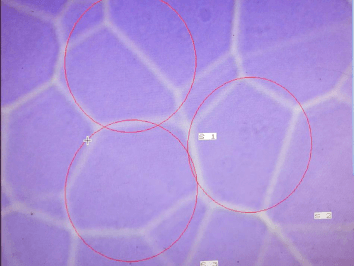

A chemical process (usually soaking) is used to transform the glass surface from a smooth one to one with tiny particles. This requires a complex mix of reactions, including ionic equilibrium, chemical changes, dissolution and recrystallization, and ion exchange. The anti-glare (AG) effect and the size/shape of the particles depend on factors such as the composition of the ingredients, concentration, reaction time and temperature. This makes production a challenge and requires advanced technology

Properties:

1.Uniform coating thickness: The etching process generally results in a uniform coating thickness, which ensures even glare protection over the entire surface.

2.Durability: Etched glass is often particularly durable and resists wear, scratches and abrasion over time.

According to the tests by industry insiders, sprayed glass can only be rubbed 4,856 times with steel wire balls, while the chemically etched AG glass can be rubbed at least 15,000 times. Of course, in reality, no one would use steel balls to rub AG glass. The example here is just to illustrate that etched AG glass is more durable than sprayed AG glass.

3.Fine detail and clarity: Etched glass can provide finer detail and greater clarity, contributing to better resolution and visual performance.

Comparative analysis: Etched vs. sprayed AG glass

Advantage of Etched AG Glass

1.Increased durability:

The physical alteration of the glass surface through etching can make it more resistant to wear, scratches and abrasion over time, whereas the sprayed coating is at risk of falling off with prolonged exposure to sunlight, oxidation, touching, etc.

2.Fine detail and clarity:

Etched AG glass can provide finer detail and greater clarity on the glass surface, contributing to better resolution and visual performance. This is especially beneficial in applications where high image quality is critical.

3.Environmentally friendly:

The etched anti-glare layer (AG) contains no volatile substances and is halogen-free, which complies with the standards required for European Union products.

Disadvantage of Etched AG glass:

Higher costs:

In the standard specification, processing a 65-inch glass by spraying costs about 6-8 US dollars. If etching is used to process the same size glass, the cost will be $12-15 or more.

Conclusion

After a comprehensive analysis of the features and benefits of etched and spray-coated AG glass, we recommend the use of etched anti-glare glass to our professional customers. Although etched glass is slightly more expensive initially, the long-term durability and superior optical performance can justify the investment. The benefits of precise texture control, uniform coating thickness, superior durability and enhanced clarity make etched glass the optimal choice, especially in areas where visibility, durability and optical performance are of paramount importance.

Our dedicated team is available to discuss individual needs, answer questions and work with our customers to deliver IFPD solutions that exceed expectations.